Browse Challenging Terrain with Confidence: Komatsu Undercarriage Parts Selection Overview

Browse Challenging Terrain with Confidence: Komatsu Undercarriage Parts Selection Overview

Blog Article

Explore Undercarriage Parts for Your Equipment Requirements

Comprehending the parts that make up the undercarriage and the significance of picking the appropriate parts is crucial to ensuring smooth operations and cost-efficient maintenance. As we explore the world of undercarriage components for equipment demands, a much deeper understanding into the details of this essential system will unravel, shedding light on the foundation that supports the effectiveness of your devices.

Importance of Undercarriage Upkeep

Regular maintenance of undercarriage components is essential for making certain optimum efficiency and long life of equipment. The undercarriage of heavy equipment, such as excavators, excavators, and track loaders, plays a crucial role in supporting the weight of the device, giving security on various surfaces, and permitting smooth procedure - komatsu undercarriage parts. Neglecting undercarriage upkeep can lead to pricey repairs, reduced performance, and possible security dangers

Routine inspections of undercarriage components, such as track chains, gears, idlers, and rollers, are important to identify deterioration at an early stage. Addressing issues quickly can stop further damage to the undercarriage and other parts of the machinery. Correct cleansing of undercarriage elements is also essential to eliminate dust, particles, and various other contaminants that can accelerate wear and deterioration.

Routine lubrication of undercarriage parts is an additional crucial element of maintenance to guarantee smooth motion and minimize friction between elements. Furthermore, tracking the use hours and maintaining maintenance records can help in organizing prompt substitutes and extending the overall lifespan of the machinery. By prioritizing undercarriage maintenance, devices proprietors can maximize performance, reduce downtime, and inevitably reduce repair expenses in the future.

Sorts Of Undercarriage Components

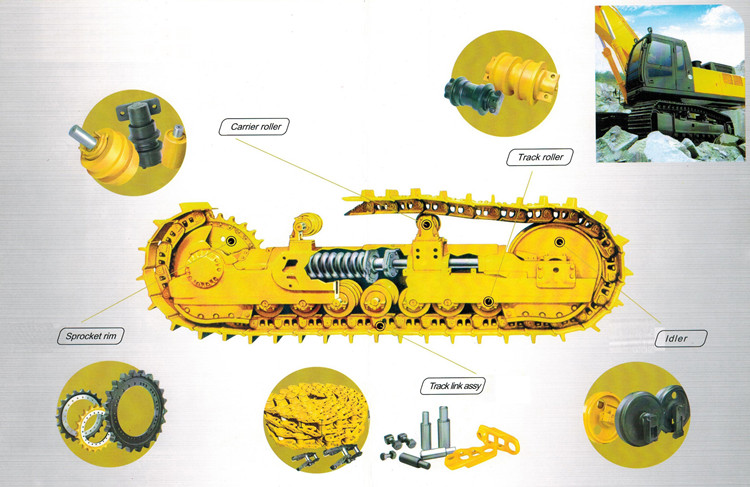

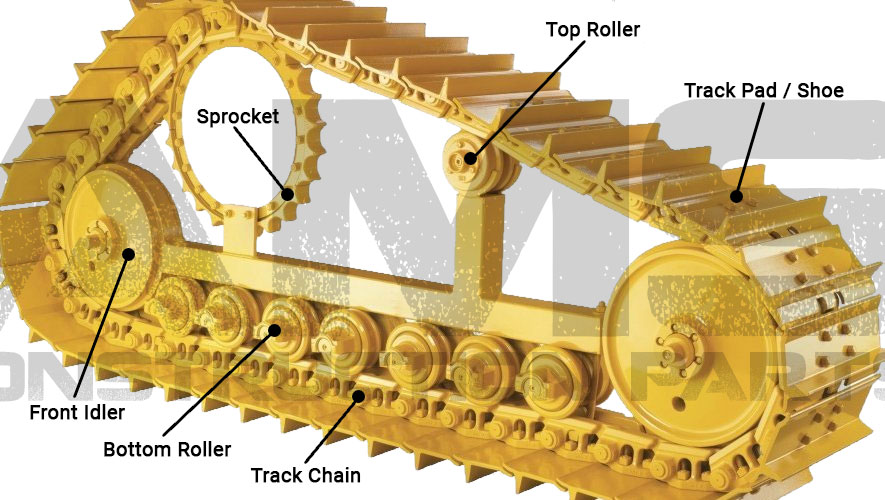

Maintenance of undercarriage components is important for equipment longevity; recognizing the various kinds of undercarriage elements is critical for efficient upkeep techniques. Undercarriage components vary depending on the type of machinery and its intended usage. Common kinds of undercarriage components consist of track chains, track footwear, rollers, idlers, gears, and track frameworks.

Track chains are accountable for thrusting the machinery onward and sustaining the weight of the devices. Track frames serve as the structure for the whole undercarriage assembly, linking all the elements together.

Regular examination and maintenance of these undercarriage components are necessary to prevent expensive repairs and downtime. By comprehending the function of each kind of undercarriage component, equipment operators can make certain optimum performance and expand the life-span of their devices.

Variables to Consider When Selecting Components

Another essential variable is compatibility with the particular equipment design. Each item of machinery might have unique demands for undercarriage parts, including size, style, and requirements. Ensuring that the components are suitable with the equipment will help avoid functional problems and premature wear.

Furthermore, it is important to think about the operating conditions in which the machinery will be used. Variables such as terrain, weather, and usage frequency can all impact the wear and tear on undercarriage parts. Picking components that are made to withstand the particular operating conditions can help extend the life of the machinery and decrease upkeep expenses in the long run.

Benefits of High-Quality Undercarriage Components

High-quality undercarriage components play a crucial role in enhancing machinery performance and expanding its functional longevity. One of the primary advantages of making use of high-quality undercarriage components is improved performance.

Additionally, high-quality undercarriage components add to set you back financial savings in the lengthy run. While the preliminary financial investment may be higher compared to basic parts, the durability and durability of premium components minimize the requirement for frequent replacements and repair work. This not just minimizes downtime yet also decreases upkeep costs, inevitably leading to higher general efficiency and productivity for organizations that rely on hefty machinery.

In addition, remarkable undercarriage parts improve security by minimizing the danger of unforeseen failings or crashes. The raised security and efficiency offered by top notch elements produce a safer working atmosphere for machinery drivers and those great site operating in close distance to the devices. Ultimately, choosing top quality undercarriage parts is a strategic decision that produces numerous advantages in terms of efficiency, cost-efficiency, long life, and security.

Tips for Extending Undercarriage Life-span

To take full advantage of the long life of undercarriage parts for equipment, applying proactive care techniques is important for guaranteeing ideal efficiency and durability. Frequently evaluating the undercarriage parts for indicators of wear and tear, such as worn-out tracks, loosened bolts, or harmed rollers, is crucial. Attending to these concerns quickly can stop further damage and expand the life-span of the undercarriage. In addition, maintaining proper track stress is vital to decrease premature wear on the elements. Over-tightened tracks can result in increased tension on the undercarriage, while navigate to this site loose tracks can cause imbalance and unequal wear.

Running the equipment within suggested guidelines, such as avoiding excessive speeds or overloading, can also contribute to extending the undercarriage lifespan. By following these tips, equipment proprietors can make certain optimum performance and durability of their undercarriage parts.

Verdict

To conclude, maintaining the undercarriage components of equipment is crucial for ideal performance and durability. By recognizing the different kinds of undercarriage parts and factors to consider when selecting them, organizations can ensure their tools operates successfully. Purchasing premium undercarriage parts not only improves efficiency yet also decreases downtime and expensive repair work. By adhering to correct upkeep techniques, organizations can extend the lifespan of their undercarriage elements, inevitably conserving money and time in the future.

Routine upkeep of undercarriage parts is essential for making certain optimum efficiency and durability of machinery.Upkeep of undercarriage components is essential for machinery longevity; recognizing the various kinds of undercarriage parts is important for reliable maintenance practices.When selecting undercarriage components for equipment, it is essential to consider news different factors to make sure optimal efficiency and durability.To optimize the durability of undercarriage components for equipment, carrying out positive care practices is necessary for making sure optimal efficiency and toughness. By adhering to these ideas, machinery owners can guarantee optimum performance and toughness of their undercarriage parts.

Report this page